Send us email

rita@gywaterjet.comCall us

+86-18736032500The construction industry is transforming with high-pressure water jet technology that achieves surface roughness depths of 0.5mm or more with incredible precision and efficiency.

The construction industry has witnessed a significant transformation in surface preparation techniques with the introduction of high-pressure water jet technology. Among these advancements, 2000bar high-pressure water wall roughening machines have emerged as game-changing equipment for concrete surface treatment.

These powerful systems operate at 2000 bar (29,000 PSI) pressure with water flow rates typically ranging from 8 to 20 liters per minute, providing an efficient, eco-friendly solution for creating optimal surface conditions for plastering, tiling, and concrete bonding applications.

Technical Specifications of 2000bar High-Pressure Water Roughening Systems

High-pressure water roughening machines are engineered for exceptional performance in construction applications:

Operating pressure: 2000 bar (200 MPa / 29,000 PSI)

Water flow rate: 8-20 L/min

Power requirements: 18.5-75 kW, typically 380V/50Hz industrial electrical supply

Drive options: Electric motor, diesel, or gasoline engines

Weight: 2000-2500 kg

Dimensions: Approximately 1200×600×1500mm to 275×165×175cm

The heart of these systems is their American or German-made high-pressure plunger pumps, which feature stainless steel pump heads, nickel-plated alloy plungers, and forced water cooling systems for continuous operation durability.

How High-Pressure Water Roughening Works

The process utilizes the tremendous energy of pressurized water to transform smooth concrete surfaces into ideal textured substrates:

Water is pressurized to 2000 bar through a high-pressure pump system

The pressurized stream is expelled through specialized nozzles forming a "water knife"

This jet stream removes the concrete's surface mortar layer

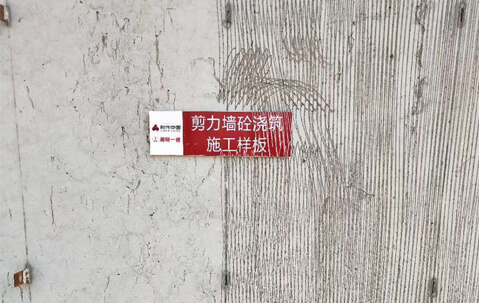

The result is a uniform rough surface with ≥0.5mm groove depth 1 and ≥1 groove per square centimeter

This technique effectively eliminates form release agents 5 that often compromise adhesion in aluminum formwork and prefabricated component applications.

Advantages Over Traditional Roughening Methods

The transition to high-pressure water roughening technology offers substantial benefits:

Superior Adhesion: Creates an ideal surface profile for maximum bonding strength

Elimination of Hollow Areas: Prevents hollow drums and (falling off) 9 that plague traditional methods

Reduced Processing Steps: Eliminates the need for plastering, leveling, hanging nets, and other intermediate steps

Environmental Benefits: No dust pollution 1, only minimal wastewater that quickly air dries

Material Savings: Requires no additional bonding agents or special materials

Process Flexibility: Can be customized for different groove depths and densities

Application Scope and Effectiveness

2000bar high-pressure water roughening machines excel in multiple construction scenarios:

Aluminum formwork concrete walls

Prefabricated components (PC)

Cast-in-place concrete structures

Renovation projects with old and new concrete combinations

Industrial cleaning of heat exchanger tubes, boilers, and ship hulls

The technology is particularly effective on smooth surfaces left by aluminum formwork 5, which traditionally challenge adhesion with residual form release agents.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: