Send us email

rita@gywaterjet.comCall us

+86-18736032500|

Name |

Details |

|

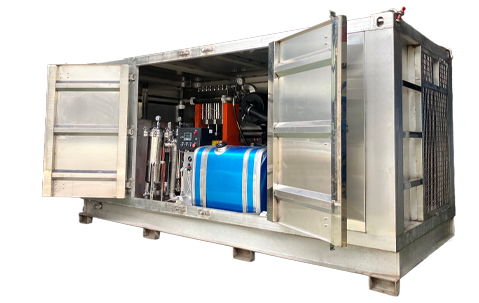

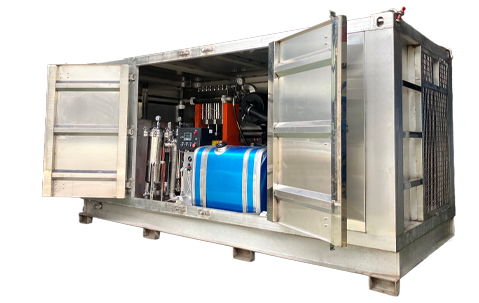

Model |

GYB-5-120/1600 |

|

Rate Pressure |

1600 bar / 23200 psi |

|

Water flow |

120 L/min |

|

Plunger diameter |

35mm |

|

Inpurt speed |

1480 rpm |

|

Pump speed |

366 rpm |

|

Plunger stroke |

120 mm |

|

diesel engine drive |

Power:440kw |

The GYB-5-120/1600 is a heavy-duty, diesel-driven high-pressure water jetting system engineered for extreme industrial cleaning tasks. Combining a massive output of 120 Liters Per Minute with an intense pressure of 1600 Bar, this unit delivers unparalleled cleaning and descaling force. Powered by a robust 440 kW diesel engine, it is designed for reliability, continuous operation

|

Name |

Quantity |

|

High pressure hose |

50 meters |

|

High pressure gun |

1 set |

|

Fan-shaped nozzle |

2 pcs |

|

Cylinder-shaped nozzle |

2 pcs |

|

Flexible gun |

10M |

|

Flexible Gun Nozzle |

4pcs |

|

Steel Gun |

1.5M |

|

Steel Gun Nozzle |

4pcs |

|

Foot control Valve |

1pc |

|

Spare Parts |

1 set |

Pipe & Vessel Descaling: Removing hard scale from large industrial pipes, reactors, and tanks.

Surface Preparation: High-speed coating removal and concrete hydro-demolition.

Heavy Equipment Cleaning: Cleaning mining trucks, excavators, and construction machinery.

Marine & Offshore: Hull cleaning (with appropriate water recovery systems) and dock maintenance.

Civil Engineering: Cleaning bridges, tunnels, and concrete structures.

9. Machine producing plant, volume / pipe / tank / rust / oxide skin cleaning…

Extreme Performance: 1600 Bar (23,200 PSI) at 120 Liters Per Minute (31.7 GPM). This powerful combination ensures rapid removal of the toughest deposits, coatings, and scale.

Powerful Diesel Engine: Driven by a high-torque 440 kW (590 HP) diesel engine, providing dependable power and eliminating the need for an external electrical supply. Ideal for construction sites, mining, and field operations.

Rugged Triplex Pump: Features a durable crankshaft-driven triplex plunger pump, designed for long service life and continuous duty under extreme pressure. Ceramic plungers and hardened steel valves ensure superior wear resistance.

Integrated Safety Systems: Includes safety relief valve, engine monitoring systems (oil pressure, coolant temperature), and emergency stop for complete operational safety.

Efficient Cooling System: A large-capacity heat exchanger ensures optimal operating temperatures for both the engine and the high-pressure pump, preventing overheating during prolonged use.

Robust Chassis & Mobility: Built on a heavy-duty steel frame with pneumatic wheels and a tow hitch, making it highly mobile and suitable for transport between job sites.

User-Friendly Control Panel: Centralized controls with clear gauges for pressure, water flow, and engine diagnostics allow for easy operation and monitoring.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: