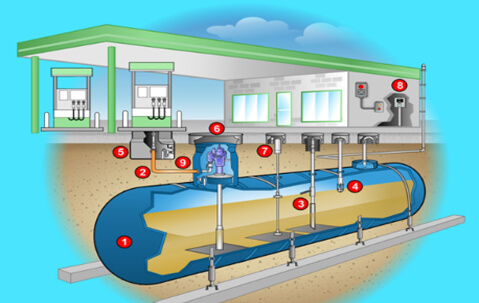

Underground storage tanks (USTs) are a critical component of gas stations, used to store fuels such as gasoline, diesel, and other petroleum products. Over time, these tanks can accumulate sludge, sediment, and other contaminants that may compromise their integrity and efficiency. High-pressure water cleaning is a widely adopted method for maintaining and cleaning USTs, ensuring their safe and efficient operation.

USTs are prone to the buildup of residues due to the nature of the stored products. These residues can include: Sludge: A mixture of water, dirt, and degraded fuel components. Sediment: Solid particles that settle at the bottom of the tank. Corrosion Products: Rust and other byproducts of metal degradation.

High-Pressure Water Cleaning Process High-pressure water cleaning involves the use of specialized equipment to deliver water at extremely high pressures, typically ranging from 10,000 to 40,000 psi (pounds per square inch).

The process includes the following steps:

Preparation:

The tank is emptied of all fuel and vented to ensure no flammable vapors remain. Safety measures are implemented, including the use of personal protective equipment (PPE) and ensuring proper ventilation.

Inspection:

A preliminary inspection is conducted to assess the level of contamination and identify any structural issues.

Cleaning:

High-pressure water jets are directed into the tank through access points. The jets dislodge sludge, sediment, and other contaminants from the tank walls and bottom. The dislodged materials are then removed using vacuum trucks or other extraction methods.

Rinsing:

The tank is thoroughly rinsed with clean water to remove any remaining residues.

Inspection and Testing:

A post-cleaning inspection is conducted to ensure all contaminants have been removed. The tank may also be tested for structural integrity and leaks.

Disposal:

The collected waste is disposed of in accordance with environmental regulations.

High-pressure water cleaning is an essential maintenance practice for underground storage tanks at gas stations. It ensures the safe and efficient operation of USTs, prevents environmental contamination, and extends the lifespan of the tanks. By adopting this method, gas station operators can maintain compliance with regulatory standards and provide high-quality fuel to their customers.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: